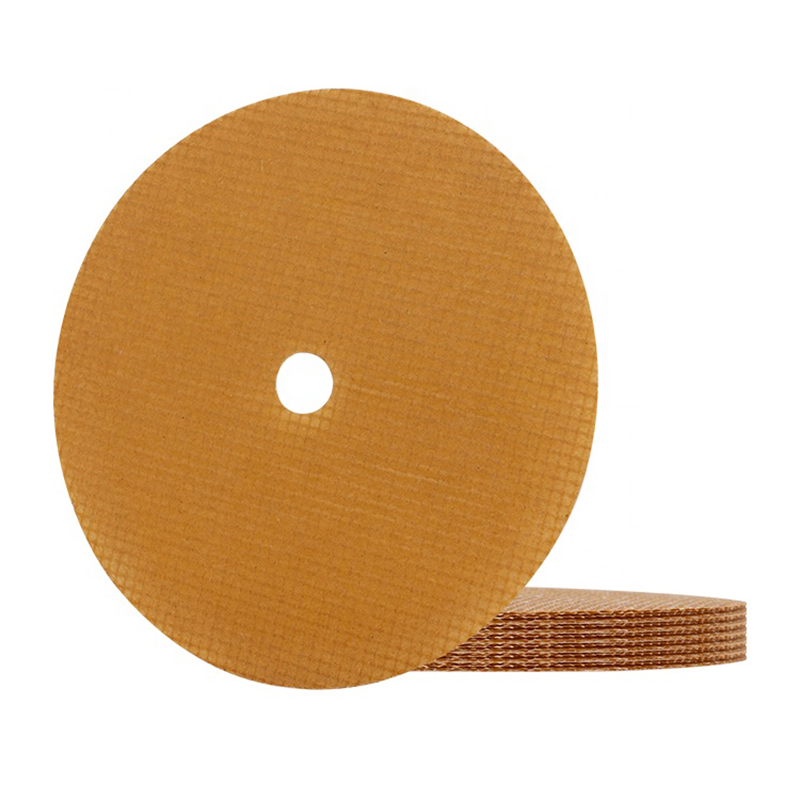

Polishing Abrasive Fiberglass Backing Plate For Flap Discs

High Quality plate fiber glass backing for abrasive discs

Abrasives Fiberglass backing pads for flap discs abrasive tools

Abrasive fiberglass backings plate for premium quality flap discs

T27 T29competitive quality abrasive fiberglass backing plate for flap discs

Low Price Custom 90mm Fiberglass Backing Plate For Flap Discs

Quality Custom Inch Fiberglass Flap Discs Abrasive Backing Plate

Hot Sales T27 T29 Abrasive Fiberglass Backing Plate For Flap Discs

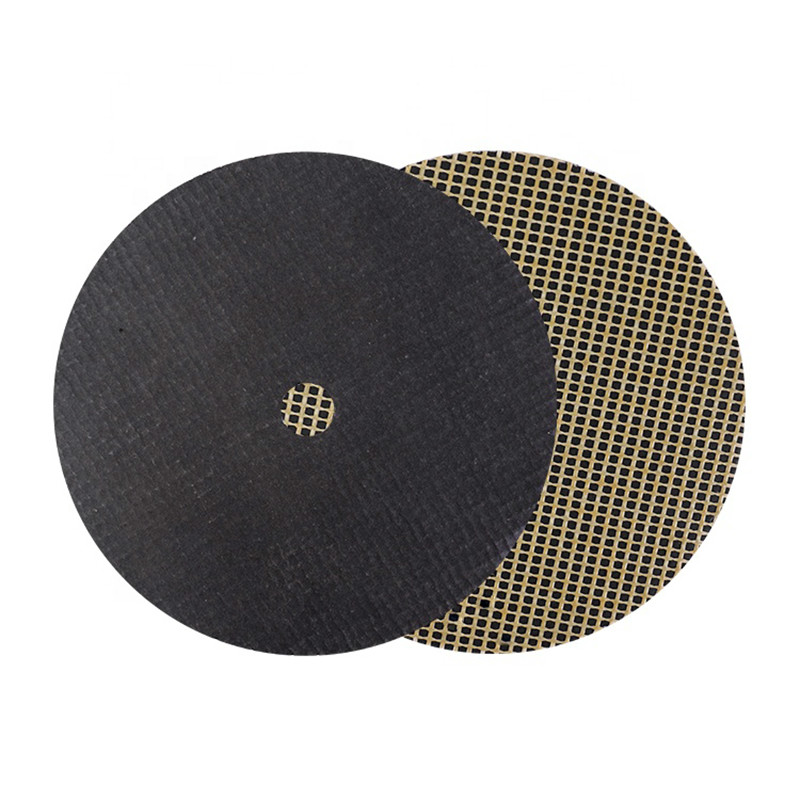

Phenolic resin liquid mesh cloth

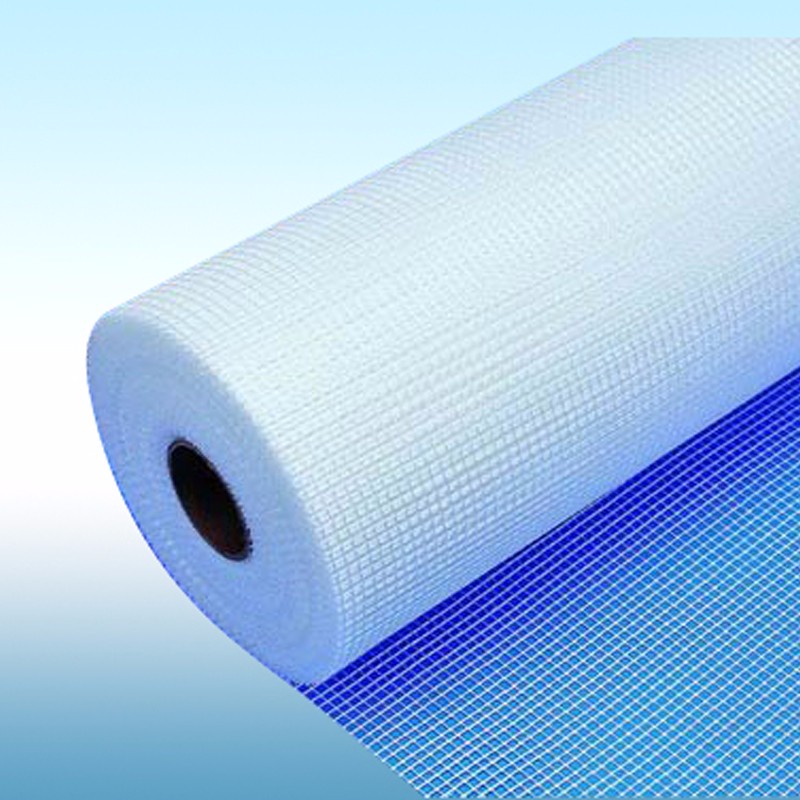

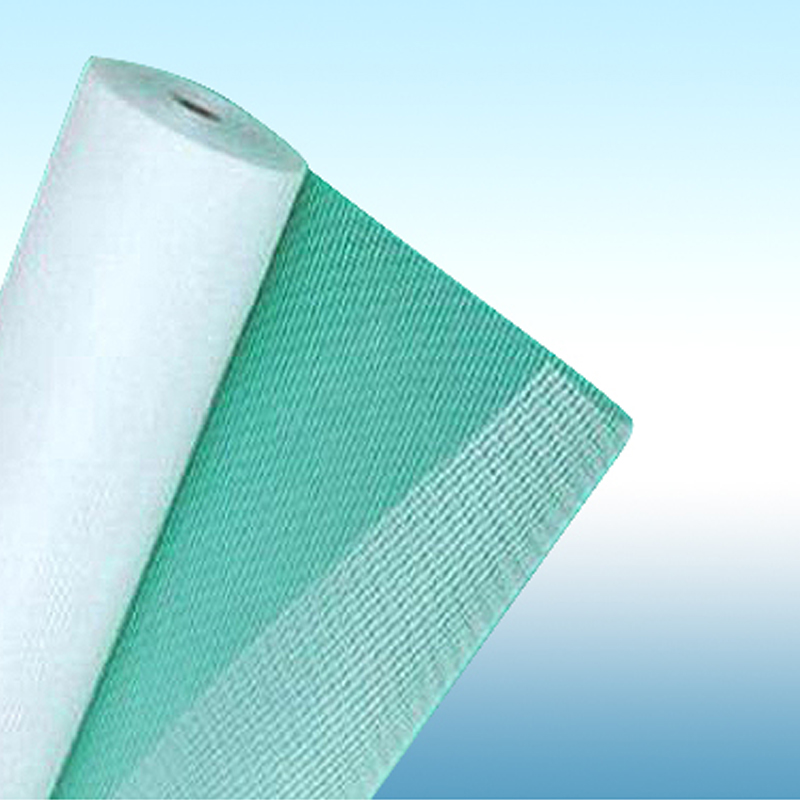

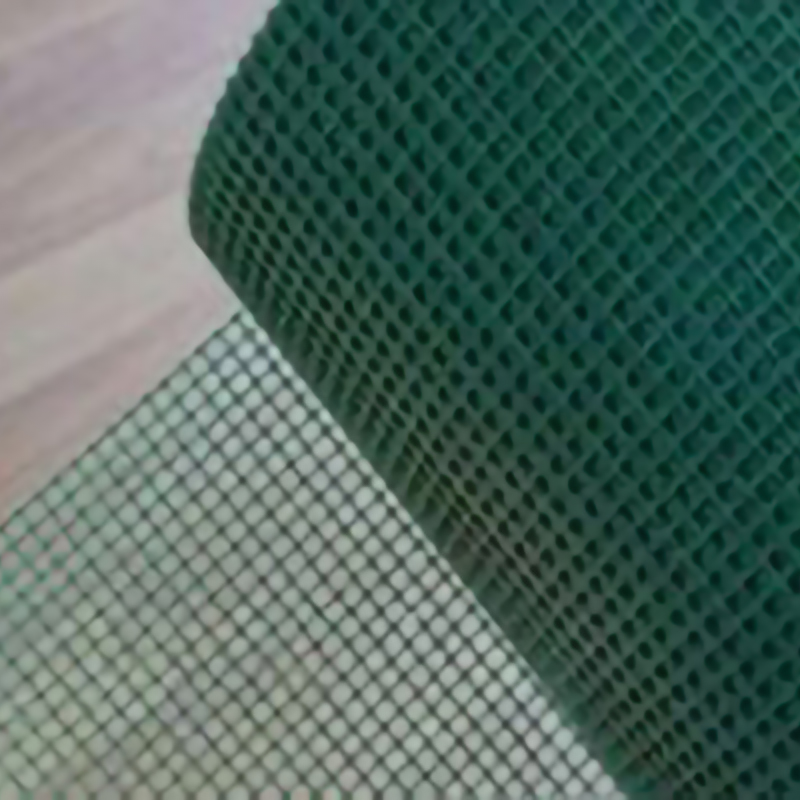

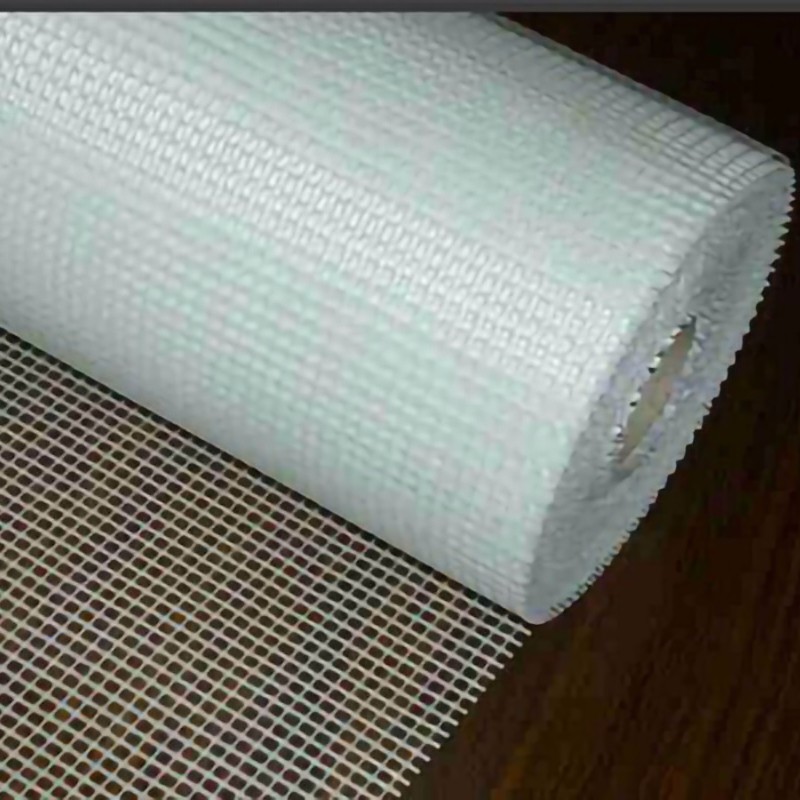

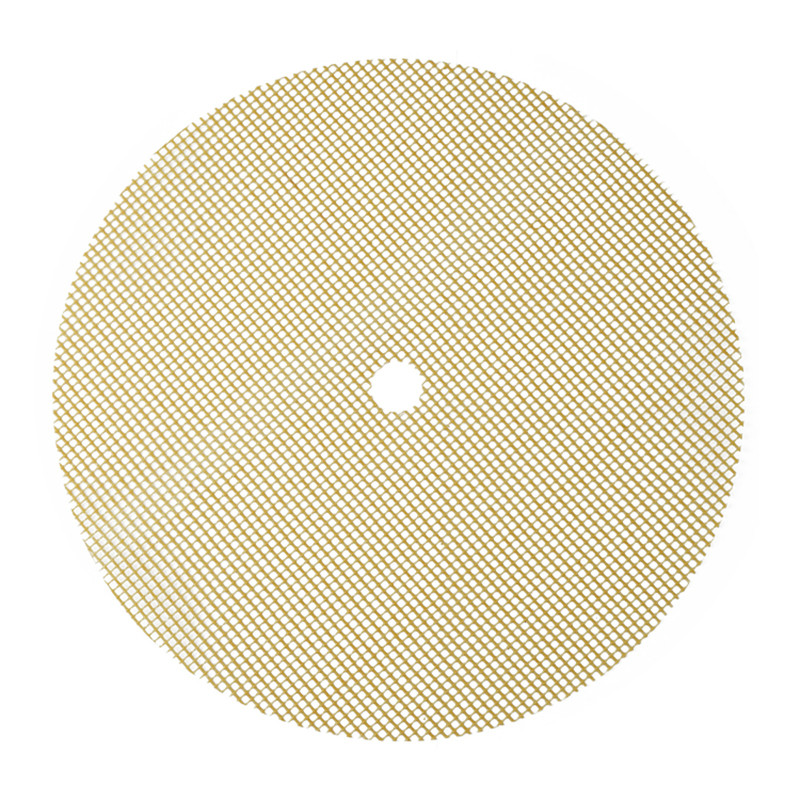

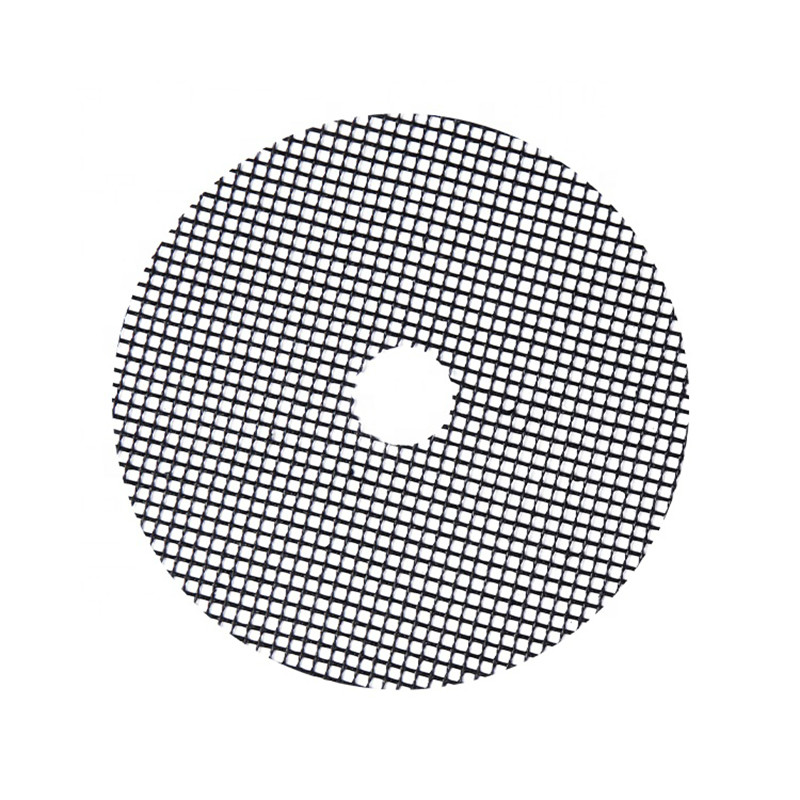

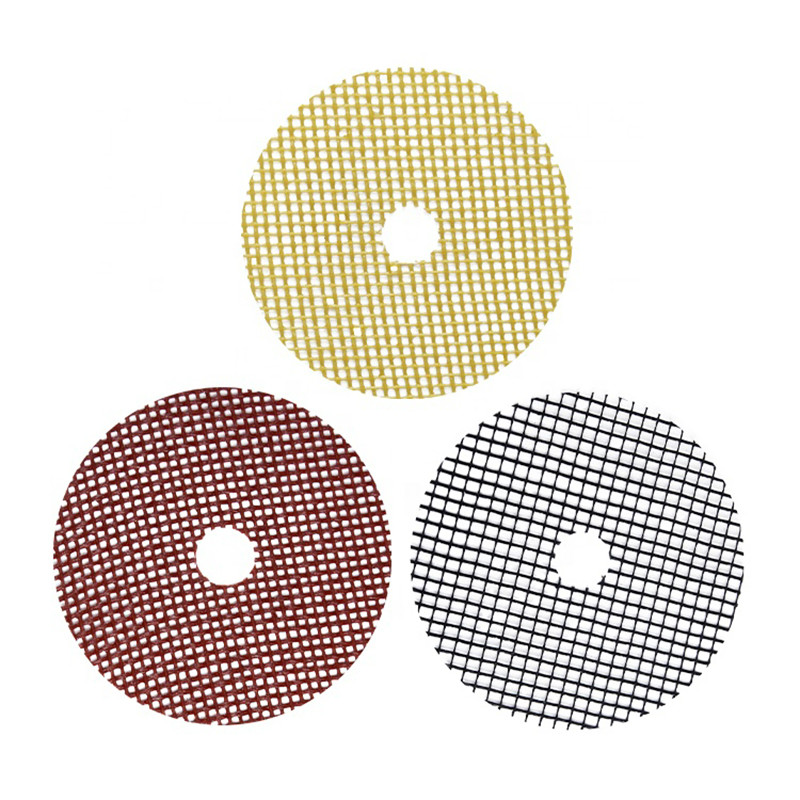

Fiberglass mesh

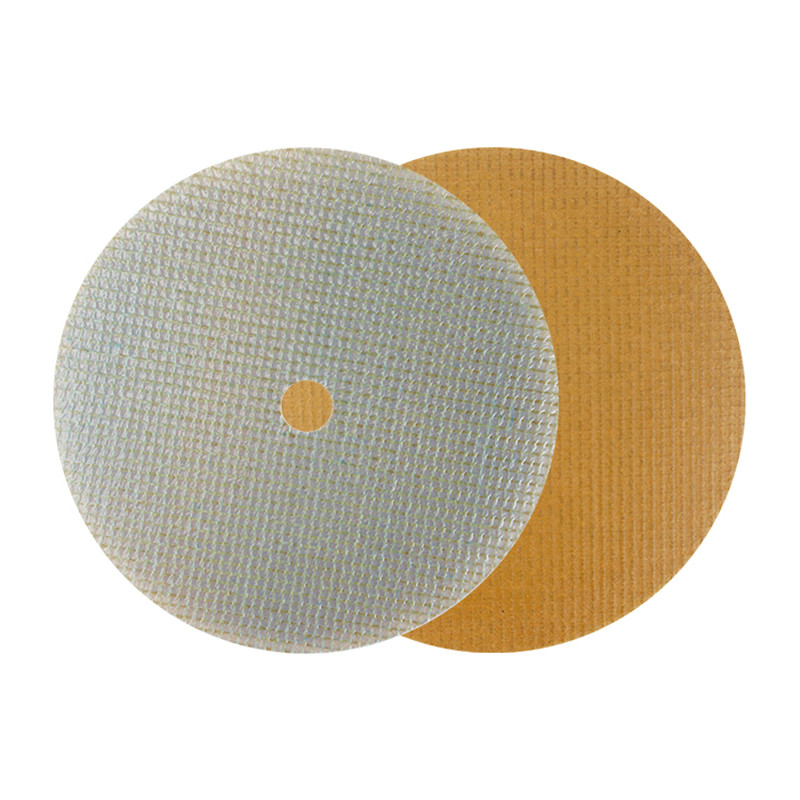

Fiberglass Fabric (Mesh Fabric and Plain Fabric)

Fiberglass Fabric (Mesh Fabric and Plain Fabric)

Fiberglass Fabric (Mesh Fabric and Plain Fabric)

Fiberglass Fabric (Mesh Fabric and Plain Fabric)

Fiberglass Fabric (Mesh Fabric and Plain Fabric)

Fiberglass Fabric (Mesh Fabric and Plain Fabric)

High Quality Reinforced Non-Alkali Fiberglass Net Discs

High Quality Reinforced Cutting Discs Fiberglass Mesh Net

Factory Wholesale Fire Resistance Cutting Discs Fiberglass Mesh Net

Chinese Complete Production Line Cutting Discs Fiberglass Mesh Net

Hot Sale Quality Plain Woven Fiberglass Mesh net

Low Price 3.5mm-20mm Alkali-Resistant Strongest Fiberglass Mesh Net

China High Quality Alkali-Resistant Fiberglass Mesh Net

1The glassfiber backing plates made of high quality raw material that platinum wire drawing process to produce , so that the product has better anti-decay performance and heat resistance and cold resistance!

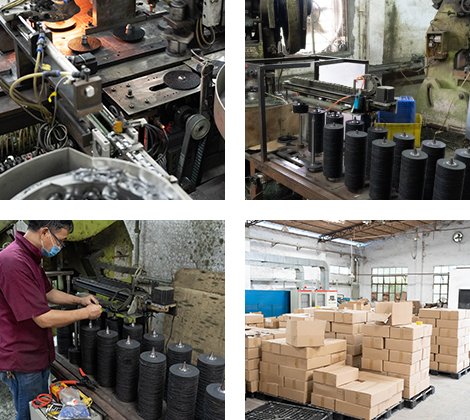

Adopting stamping forming,which maximizes the concentricity ,size accuracy and user’s safety.

If adopts grinding to do the forming, the tolerance of concentricity will be bigger ,which may cause shaking(trembling) while the plate’s in a high-speed rotating working condition, might put user in danger.

2Stamping forming - Our product adopts punch blanking forming, with the best concentricity and higher dimensional accuracy.Using the traditional grinding machine edge grinding method to form, concentricity error is large.In this way, when the customer is in use, the glassfiber backing plates with large concentricity error will produce jitter in the case of high-speed rotation. If the plates are made thinner, this kind of plates normally show higher strength while being tested,but high-hardness and the lack of pliability makes them perform worse on synchronous consumption and the actual using.Therefore,with guaranteed strength, our plates are better for synchronous consumption, and more unlikely to cause scars on the surface of the grinded objects.

3The qiansheng glassfiber backing plates with On the premise of ensuring safety strength, the thickness is increased by 5-10%, so the synchronous consumption is better, and the flexibility is maintained;It is not easy for users to form trauma or marks on the workpiece surface when polishing.At the same time,the plates leaves enough space for the resin to bond the sand belt, so that the sand belt bond more firmly. Using special materials and proper combination of fiberglass resin mesh, our plates have unique appearance and smooth surface.

4The surface of the net cover is flat and more beautiful;Special material and reasonable mesh collocation are adopted to make the surface of the mesh cover smooth and beautiful. We own the patent for invention of the backing plates manufacturing machine, which is specially invented for producing backing plates with high efficiency,unified sizes and low tolerance.

5Special equipment with independent invention patent.The production equipment has the independent invention patent, specially develops for the production glass fiber net cover, the production efficiency is high, the product size is uniform, the error is small.

6Complete inspection is adopted for finished products with high quality rate.